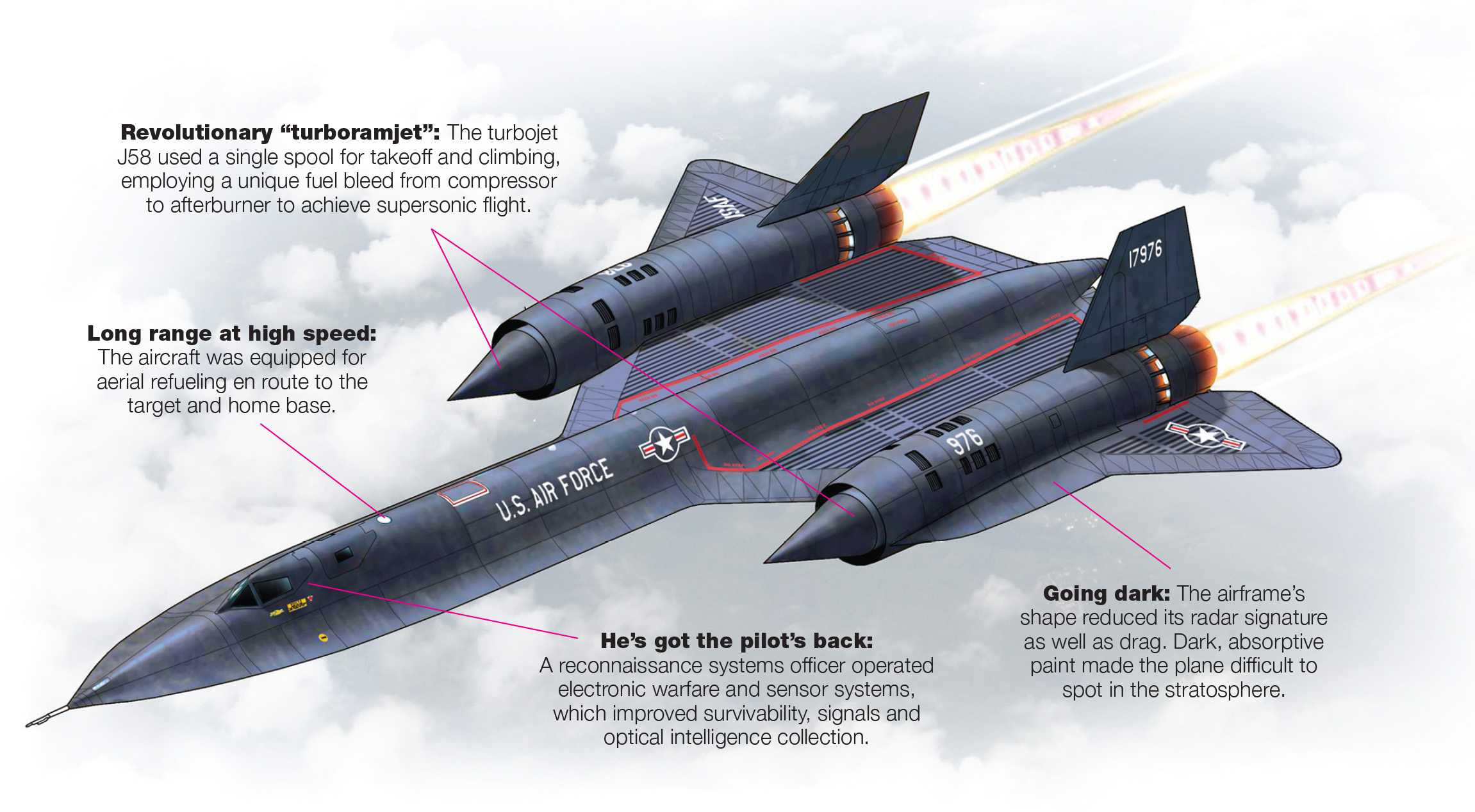

Sr 71 Engines - The Pratt & Whitney J58 (company designation JT11D-20) was an American jet engine that powered the Lockheed A-12 and later the YF-12 and SR-71. It was an afterburner turbojet engine with a unique compression afterburner that bled the afterburner and provided increased power at high speeds. Because of the aircraft's wide airspeed range, Jane needed two modes of operation to propel it above 2,000 mph (3,200 km/h) from rest on the ground. It was a conventional fuel turbojet for takeoff and acceleration up to Mach 2.

Above Mach 2 for Afterburner. Jane's cruising performance has led her to be described as "acting like a turbojet".

Sr 71 Engines

It has also been described as a turbo ramjet based on erroneous reports describing the turbomachine as completely bypassed.

Pratt & Whitney J58

Over the years, the Jane figure has served CIA and USAF mission requirements, and was later modified slightly for NASA experimental work (carrying external payloads aboard the aircraft), which required more thrust to withstand the aircraft's high drag.

Named after JT11, J58 is derived from the great JT9 (J91) gene. It was a 3/4 scale JT9, reduced from 400 lb/s (180 kg/s) to 300 lb/s (140 kg/s).

It has also been recommended for various naval and air force aircraft, e.g. Convair F-106, North American F-108, Convair B-58C, Vought XF8U-3 Crusader III, and North American A3J Vigilante, but none of these applications were implemented.

The P6M began with Allison J71-A-4 engines, but switched to the Pratt & Whitney J75 due to J58 development delays. After the P6M was canceled, it was selected for the Convair Kingfish and the Lockheed A-12, YF-12A, and SR-71. Other sources attribute its origin to the USAF's WS-110A power requirement for the future XB-70 Valkyrie.

Sr 71 Pilot Tells The Story Of When He And His Rso Were Almost Forced To Ditch Their Blackbird Mach 3 Spy Plane After An Engine Fire

Analytical calculations of the original J58's performance stated that at Mach 2.5 "exhaust pressure equals inlet pressure, compressor deep in surge, no cool air in combustion liner and meltdown".

The first problem was caused by the compressor's supply temperature being too high, which prevented the gas generator from adding power to the gas burner to provide any power. All the pressure in the jet tube came from the ram, as in a ramjet, and not from the gas generator. Fuel can only be added to the burner, which becomes the sole source of the Gin. Based on patented design changes, the speed of the gas generator increased from about Mach 2.5 to Mach 3. Beyond this speed limit, the gas generator becomes a drag point at Mach 3.2 with a pressure ratio of 0.9.

Ev can't balance the minimum burner drag. Lockheed entry designer David Campbell described this effect qualitatively.

The second problem was that the compressor was trying to operate at very low speeds in the so-called "off-design" region of the compressor map. The third is to cool the combustion tube with superheated turbine exhaust.

Lockheed D 21b > National Museum Of The United States Air Force™ > Display

Describes changes to Jain that enhance Jain's capabilities for Mac 3.2. They include recirculation of 20% of the three compressor air through six external pipes to the burner after the fourth compressor stage. This allowed the compressor to function properly and increase the air flow to the compressor. Some of the increased flow bypasses the compressor to the combustor after stage 4, while some exits through the choke region before the final compressor stage.

More airflow gave more power. The inlet guide vanes are modified with trailing edges to reduce blade wobble and prevent blade fatigue. The afterburner is cooled by exhaust air, which is 400 °F (220 °C) cooler than the turbine exhaust. Not all of the oxygen in the bleed air is available for combustion because most of the bleed air is directed into the cooling mantle before entering the combustion chamber for reheating.

Thus, it can operate reliably for long periods of time at unprecedented temperatures, not only inside the engine, but also around the housings where the controls, accessories, wiring, fuel and oil pipes are located.

Two starting methods were used during the A-12, YF-12, and SR-71's service life: an AG330 starter carriage with two Buick V8 engines drove a common output shaft or drove a small starter adapter with compressed air. The air-start method was replaced by heavier "Bukes" and better compressed air supplies.

Pratt & Whitney J58 Turbojet

An aircraft traveling at three times the speed of sound experiences severe thermal turbulence due to frictional heating and stall ram lift. After absorbing 40,000 Btu/min (700 kW), the aircraft was the only heating fuel available.

It was delivered to the fuel lines at 600 °F (316 °C), cooling everything from the crew to the exhaust area gauge.

To withstand these high temperatures, a new jet fuel with a low vapor pressure had to be developed. A chemical method for fuel combustion was developed to match triethylborane (TEB), due to its low volatility. TEB self-ignites when exposed to air above −5 °C. Both the afterburner and the afterburner were fired by the TEP, and the afterburner had a catalytic igniter that ignited the hot turbine gas.

TEB (21.1 imp fl oz; 20.3 US fl oz), sufficient for at least 16 activations, shutdowns, or on-off lighting; This number was one of the limiting factors of the SR-71 Durance, as the afterburners had to be re-ignited after each aerial refueling.

Optimization Of Ramjet Engine Design And Combustion

When the pilot moved the throttle from the trim position to the neutral position, fuel leaked into the gin about a short time later. 50 cm

(1.8 imp fl oz; 1.7 US fl oz) TEB shot was injected into the combustion chamber, which automatically ignited and ignited the fuel with a gray flash. However, in some cases, the TEB flow was obstructed by coking deposits at the injector nozzle, hampering recycling efforts. Filling the TEB tank was a dangerous job; The maintenance crew wore silver fire suits.

In contrast, the JP-7 was much safer, allowing some aircraft to be serviced during refueling. Chemical ignition was chosen over conventional ignition for reliability and reduced mechanical complexity. The TEB tank is cooled by fuel flowing around it and contains a disc that ruptures in the event of overpressure, allowing the TEB and nitrog to spill into the afterburner.

The heat source requires a two-stage reduction. Before the fuel heater system became dangerous, the ECS air from the gain compressor was too hot at 1,230°F (666°C) and the air was at 760°F (404°C).

The Fastest Plane In The World Doesn't Need Armor

Should have used it first. Fuel flowing from the tanks to the gins was used to cool air conditioning systems, aircraft hydraulic fluid, gin oil, auxiliary drive system oil, TEB tank and fuel nozzle engine control lines.

Development of the J58 involved some of the most challenging metallurgical development challenges ever experienced by Pratt & Whitney Aircraft, with compounds operating at unprecedented temperatures, stress and durability levels.

New manufacturing technologies and new alloys require the development of surface coatings to improve mechanical properties and protect components.

Mar-M200, the strongest cast nickel-base alloy, has prevented the premature fracture of conventionally cast (ie, equiactive) turbine blades and blades by developing components that are strengthened in the direction of casting in the same material. Orientation hardened Mar-M200 has become the strongest cast turbine material to date and has been introduced into industrial refineries. MAR-M200 cast monocrystalline turbine caps, which further improve high temperature resistance, are tested and developed on J58 engines. Waspaloy was the most widely used alloy in alloys, from critical high-energy rotating compressor discs to sheet-to-sheet composites. Although used for turbine discs in other engines, it did not have the properties required for the J58 turbine discs. Astroloy, the strongest nickel-based superalloy known in the West at the time, was used instead. Waspaloy was also originally used for the diffuser housing that connected the compressor to the burner and contained the highest pressure in the gin. Cracking in the diffuser housing weld led to the introduction of Inconel 718 for this part. The afterburner liner was sprayed with a ceramic thermal barrier coating that allowed continuous use of the burner along with cooling air from the compressor.

An Sr 71 Blackbird's Pratt & Whitney J58 Engine

2 SR-71s on loan to NASA for research purposes. One of them was modified for the flight test of a linear airspike missile and equipped with powerful J58 engines.

Strength increased by 5% to compensate for aircraft drag. The increase in power was caused by pushing the throttle or by increasing the exhaust gas temperature by 75 °F (42 °C). The increase was limited to a permissible reduction in the lifetime (life limiting factor) of the second stage turbine caps from 400 to 50 hours. The same thrust-Hansmet studies used for this study investigated the 5% additional thrust from the additional fuel that was possible as a result of injecting the oxidizer (nitrogen oxide). Nitric oxide will be limited

Diecast sr 71 blackbird, sr 71 diecast, rc sr-71 jet with real engines, sr 71 model rocket, sr-71 engines, sr 71, sr 71 shirt, sr 71 toy, sr 71 model airplane, sr 71 blackbird toy, sr-71, lego sr 71 blackbird

0 Comments